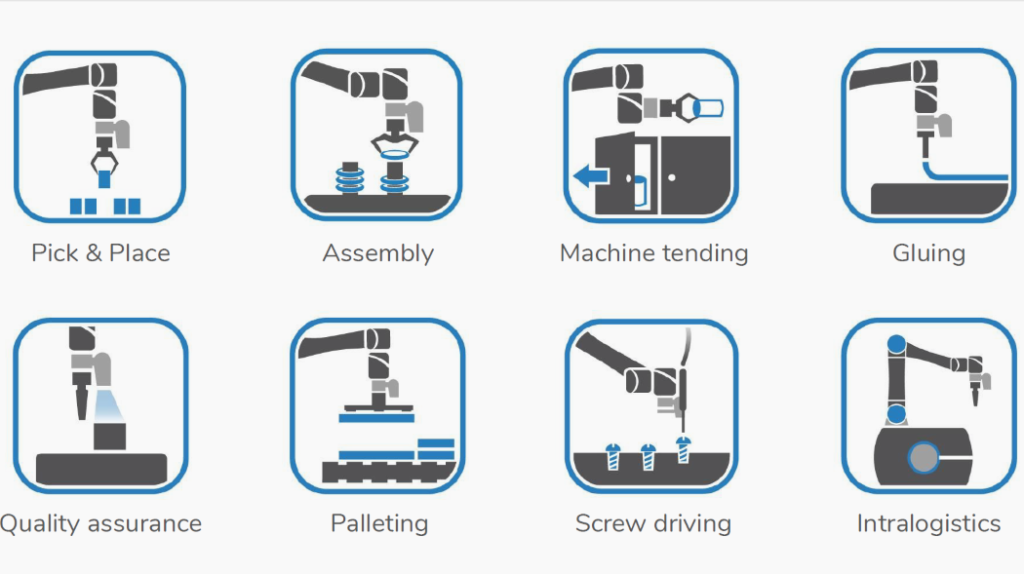

Collaborative robots can be used to build an innovative and intelligent manufacturing environment where humans and machines work in harmony.

Designed to work with both humans and machines, Omron TM collaborative robots are the latest in a long line of innovations in automation technology for industrial applications.

Omron TM collaborative robot can also be integrated to specifically planned transport cart for Omron LD platfom.

Features

1. Intuitive programming interface reduces programming time

Reduced installation and setup times compared to traditional industrial robots. The flowchart-based intuitive programming interface and easy teaching require little to no previous robot programming experience.

2. Integrated on-arm vision system reduces setup time

The TM series comes with built-in vision and integrated lighting, allowing the user to capture products with a wide viewing angle. Equipped with image-sensing functions such as pattern matching, bar code reading and color identification, this robot system makes inspection, measurement and sorting applications extremely easy to set up out of the box.

3. Conforms to all human/machine collaborative safety standards, reducing installation time

The TM series conforms with all safety standards that enable cooperation between humans and machines. It can be safely operated around people without industrial safety fencing traditionally required for industrial robots, greatly reducing the installation time. The cobot conforms to safety requirements for industrial robots ISO10218-1, as well as safety requirements for collaborative industrial robots under ISO/TS15066.

Technical Specification

All Omron TM models are available with AC or DC power supply and SEMI S2 safety certified.

| Model | Payload | Reach |

| Omron TM5-700 | 6 kg | 700 mm |

| Omron TM5-900 | 4 kg | 900 mm |

| Omron TM12 | 12 kg | 1 300 mm |

| Omron TM14 | 14 kg | 1 100 mm |

Download brochure: Omron TM Collaborative robot